The steering challenge: SNB processes 410,000 tonnes of waste water sludge every year ― 30% of the Dutch sludge produce. SNB operators need to keep their high-temperature facility in good state at all times. For instance, the oven temperature always has to stay within bounds. Now they are also asked to reduce fossil fuel consumption. This adds more complexity to their job and complicates discussions with management.

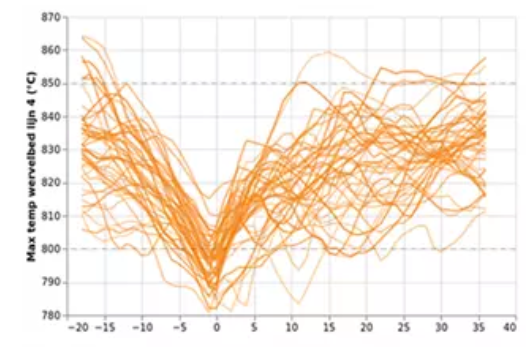

The uncertainty: Which moments of gas consumption are avoidable, and which are not? Together with SNB’s operation management and Fudura, Seita discussed which variable subset could give enough insights when bundled with a dedicated clustering algorithm. Together, we ran a pilot across multiple weeks in the summer of 2021, which resulted in the GripOnGas service.