d

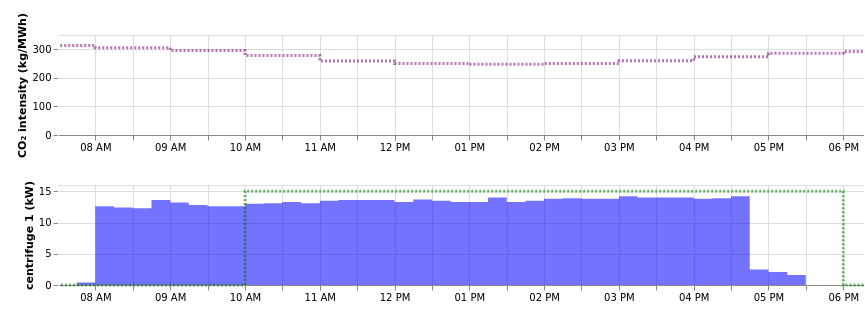

The steering challenge: The Rijnland water board runs centrifuges to clean Dutch waste water. A centrifuge should process 8 tonnes of sludge per day. Rijnland has an energy contract with fixed costs, but they want to start their journey to go green anyways. Can the centrifuge running times be adjusted so the consumed electricity is greener, on average?

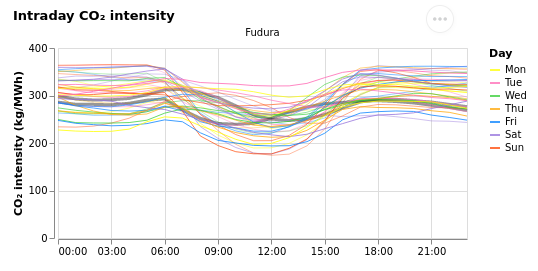

The uncertainty: How flexible are the centrifuge running times? How variable is the CO₂ content on the Dutch grid, and can it be forecasted? And as we like to actually go ahead and do things: Can smart advice about process running times be integrated in the daily operations of the engineers?

Together with Rijnland and Fudura, we’ve been running a pilot across several months in 2022. We have shown that the daily operations work well and that CO₂ can be reduced by 27% (on days when running times are indeed flexible). The next phase is underway in 2024, where we will increase automation within Rijnland’s systems and scale to more locations.

Hi Nicolas,

How does Seita Energy support real time monitoring for EVCE – i.e., low voltage (switchgear, transformers) command/control M&V?

I’m very interested in moving FLEXMEASURE type Decision Support Services at the edge into a policy-based choice ecosystem.

Optimally, evolving a telecom SIP protocol to do more real time dispatching/optimization determined by full spectrum calculation of energy attributes- such as CLS (another LF Energy project)