-

The first energy flexibility service based on top of our FlexMeasures platform: GripOnGas

-

The first successful pilot together with our corporate partner Fudura

-

The story told as it unfolded during the last months:

Collaboration with Fudura

At the end of 2020, we reacted to an innovation challenge by Fudura. Fudura is an energy metering company for corporate customers and in 2020, they were looking for innovative services, in order to create customer value from the patterns in meter data.

The perfect ESCO for Seita to explore opportunities with! In addition, Fudura also has given sustainability a central place in their strategy.

A collaborative exploration ensued, with the explicit goal to find energy flexibility valorisation opportunities around consumption processes at Fudura’s industrial customers.

In the meantime, we have done two pilots with two of their customers. We’ll talk about the second pilot in a later post, but the first one took us to Moerdijk, where a lot of heavy Dutch industry is located. We had exploration meetings with the facility operation teams (a difficult undertaking in Covid times), with all the bells and whistles, like whiteboard drawings. After a few weeks, the first version was made and the pilot started.

SNB's challenge

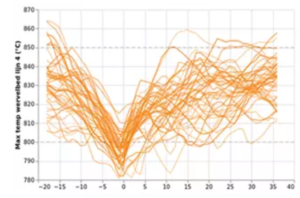

So who is this first customer? SNB processes 410,000 tonnes of waste water sludge every year ― 30% of the Dutch sludge produce. They use gas to power on their oven. The SNB operators need to keep their high-temperature facility in good state at all times.

For instance, the oven temperature always has to stay within bounds. This leads to more gas consumption. In the current climate-conscious times, SNB is looking to pioneer novel ways to minimize their gas consumption.

As such efforts add more complexity to their job and complicate discussions among operators and their management, SNB were open to co-create a data-driven solution to empower their efficiency ambitions. Fudura understood this and decided to bring Seita to the case.

Actually, Fudura has published a customer story about SNB’s case (in Dutch), where Martin L’Annee de Betrancourt, head of operations, explains their thinking.

The GripOnGas service

So what was the innovation which we proposed after sitting with SNB and Fudura for a few times? What does our new service look like?

To us, the question seemed to be this: Which moments of gas consumption are avoidable, and which are not? In the discussions, we learned that even though SNB’s facility operators look at up to eight monitors with a lot of data, there is a small set of crucial variables which can give us enough insights into separating avoidable gas consumption situations from others. We developed a dedicated clustering algorithm for this.

The way forward

Now this service is offered by Fudura and we are looking to test it out with more customers in high-temperature facilities. Exciting times. If this sounds remotely of interest to be applied to your industrial gas consumption, please get in contact with us or with Steven Barten (see link above) at Fudura!

Oh yes: Our first SaaS subscriber is ― SNB. They liked the pilot and see value in GripOnGas for their operation and future reporting. They pay monthly for our hosting of the GripOnGas dashboard and our algorithm on their data.

We are very thankful to both SNB and Fudura, as for a startup, these steps are very important milestones!

And while we’re at it, we are grateful to the Provincie Noord-Holland for co-funding our research into smarter consumption. The process analytics tools that came out of that R&D were a vital element in making this pilot a success.